Description

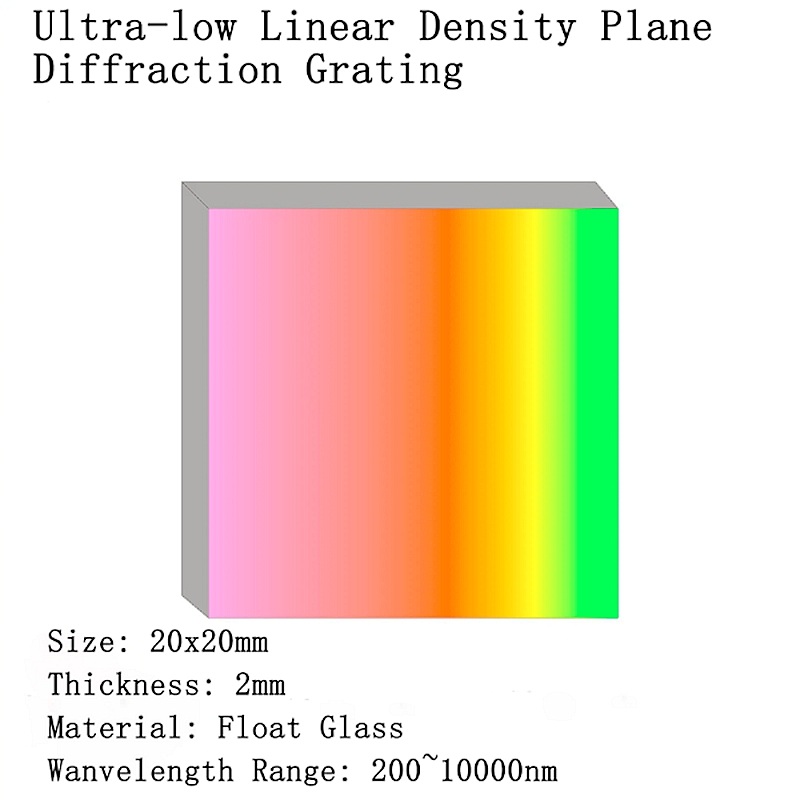

Ultra-low Linear Density Plane Diffraction Grating Spectroscopic Interference Optic Experimental Instrument Holographic Gratings

Specifications

Brand Name: SRATE

Shape: Plano

Model Number: Ultra-low Linear Density Plane Diffraction Grating

Usage: Optical

Structure: Plane

Material: Glass

Size: 20x20mm

Reviews

There are no reviews yet.