Special test

Tests on each interval of five seconds to ten times the full scale current input overload, the action is repeated nine times for each time of 0.5 secondsAfter this test, 7-14 to maintain normal.

Vibration test meter packaged in the vibration plate 1,000 times per minute, up and down 4mm shock In each direction for 10 minutes. After this test 7-14 to maintain normal impact test meter packaged 30-cm height of fall in 3cm thick wooden board, XYZ three-direction test.After this test, 7-14 to maintain normal reliability test the current input of 100,000 calibration points within the limits of current sense is still the standard environmental impact test temperature of 50 ° C, humidity 85%, for 100 hours, after this test 7-14 to maintain normal.

terminal pull test :terminals must withstand one kilogram tension, sustained 60 seconds will not be affected.

Others:

temperature limits for using:-10 degree to +60 degree RH 35 to 85%

temperature limits for Storage:-20 degree to +60degree RH 35 to 85%

—–Do not use the meter in direct sunlight, and put the meter in the box to avoid foreign matter into the meter internal.

Soldering Condition terminal about 3 mm placed in the temperature of 230 degree tin plate, placed 3.5 seconds.

After this test, 7-14 to maintain normal,

Hand-held soldering gun to solder temperature 350 degree, the terminal contact for 3.5 seconds, the terminal front-end of about 3mm contact with the solder gun.

After this test, 7-14 to maintain normal, anti-static test in the same direction three times, to characterize the difference between the pointer in the length of the scale in a transparent cover surface to dry nylon 1/3 back to the zero position.

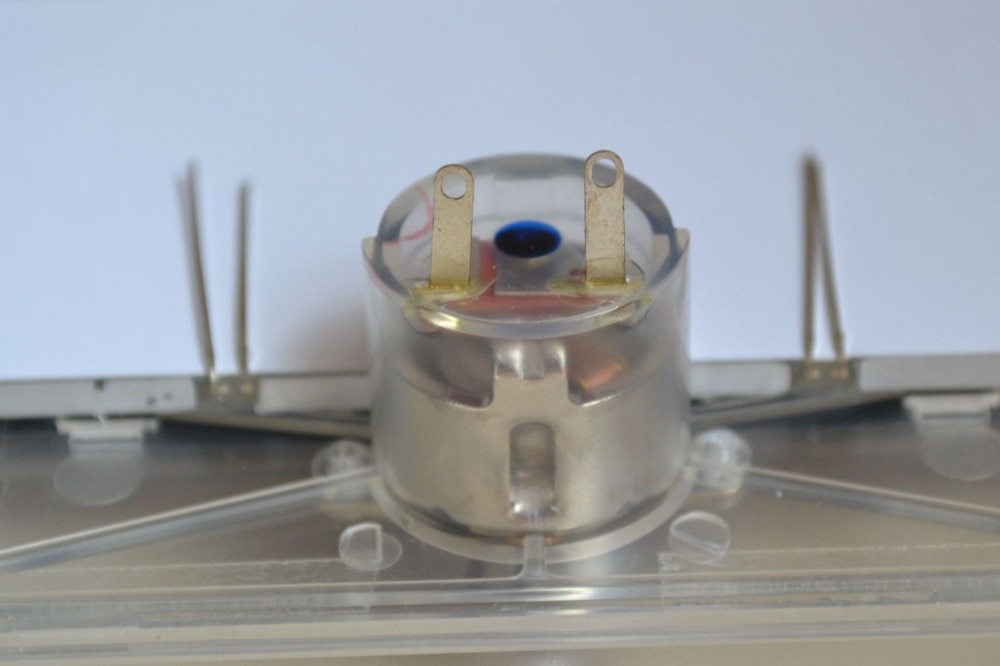

Bulb Specifications: 2x big blue LED backlighting 2.9-3.2V 20mA