Description

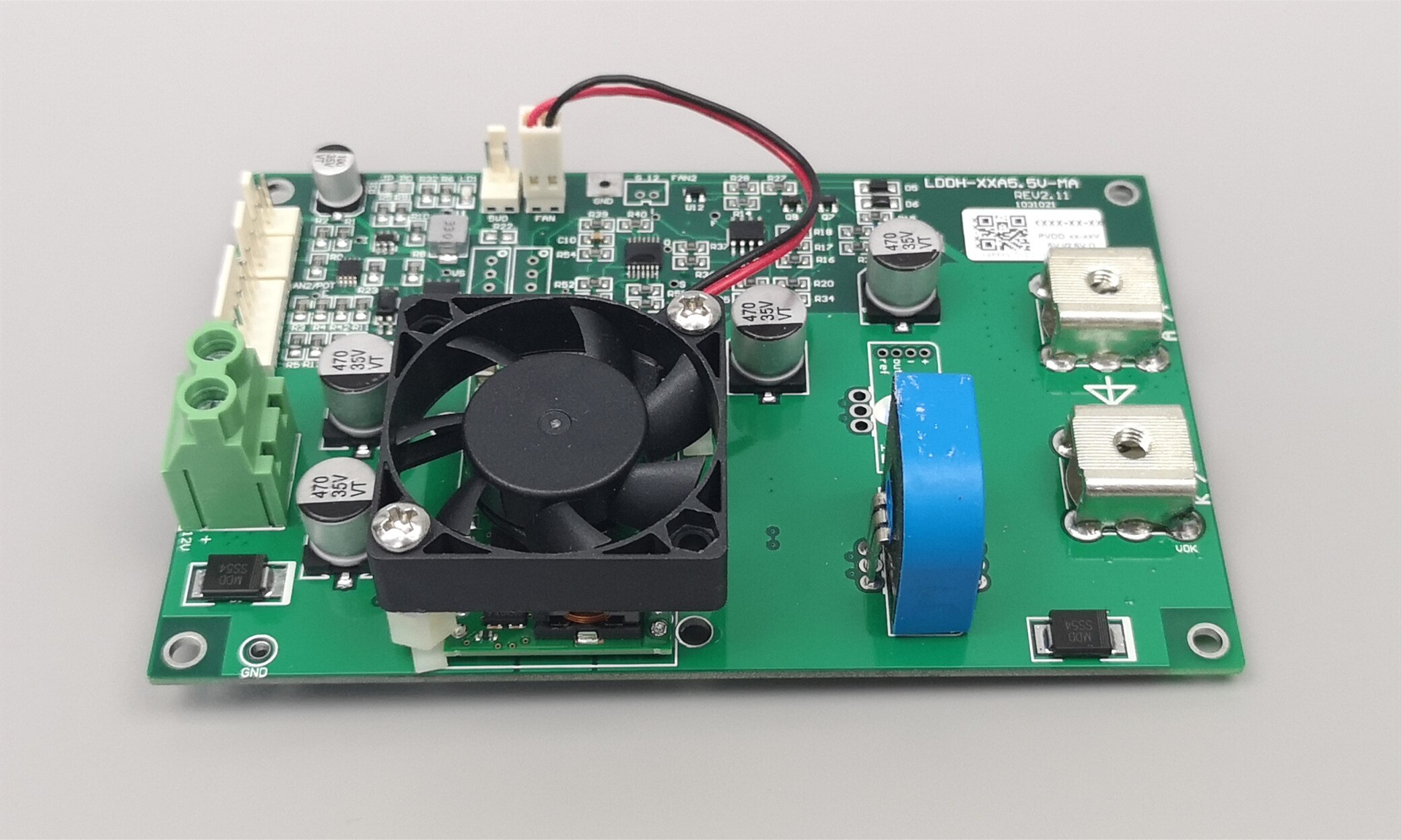

Model:LDDH-XXA5.5V-MA

0-25AVersion: Single sensor

26A-45AVersion:Current sensing,Plate force-air cooling

46-60AVersion: Bi-sensing,On-board enhanced force-air cooling

Product Features:

Suitable for single-ended(A laser diode)、Double-ended(The two laser diodes)End-pumped laser,Semiconductor、Welding、Drivers for various lasers such as optical fiber。Perfect for welding、Marking applications such。

Semiconductor laser test,LEDThe light-emitting diode、All kinds of diode tests are suitable。

The Hall sensor

High-speed,The load voltage fully adaptive!

Ripple-free!

Efficient、air-cooled,There is no special cooling requirements

To facilitate integration

Four-layer single plate thick copper design,Small size,High Reliability!

Technical parameters:

The highest adaptation voltage:5.5V,Self-adaptive

Maximum rated current:60A,Rated current specified by user,For example35A,45A

Input voltage: 12V+-10%,It is recommended to use12VThe standard switching power supply

The current rise/The rate of decline:200us

The size of:130mm*85mm*30mm(Long*Width*High)

Applicable Product example:

DILAS Single Bar A full range of products

DILAS Multi-Bar 120WAnd all of the following products

May drive a single、Two、Even three(It shall not exceed5.5VYou can)TheLDThe laser diode,Provide fast and stable constant current,Voltage fully adaptive。The specific factory default rated current can be specified by the user,For example35A,45A,The maximum can be60A! High-speed power supply,The current rise/The lower time< 200us!Suitable for welding,Marking applications such!Semiconductor laser test,LED、Various diode test。 Internal control and external control selection,That is two analog inputs。 End-pumped、Side pump、Semiconductor、Welding、Fiber Laser ideal power supply as an example,To adapt to a wide range!!

dilas 120WProducts below grade applicable for all(High current laser diode)!!coherentIdeal Power supply for similar products!

Whether it is35A,45A, Or50A,60A,A single or a doubleLDPerfect application!Of course the rated35AThe followingLDAlso no problem。The product is essentially a high-quality constant flow source,As long as it is various loads in rated parameters,Apply。

An analog input,And current monitoring output are the default0~5V(Also can be changed0-10V)For0~The highest current。An analog input,Current Monitor output,Maximum output current,Can be customized according to user needs!Factory default for customer requirements parameters!!

Interface Definition

1, PVDD The power input port /7.5mmTerminal blocks

Note:Supply voltage range8V-14V。

2,AN2/POT,Second-channel analog input terminal,Can pick up the potentiometer,Or analog /2510-3PSocket near the bed

3,CHSW Channel(Locus of control)Select/2510-2PSocket near the bed,If not, it is used by defaultCTLInterface of analog input (AI)

4,CTL The control terminal/2510-6PSocket near the bed

5,A、K The load interface /φ5Large current terminal

A: To loadLDThe positive electrode

K: To loadLDThe negative electrode

Different application configuration

1,For applications that only need one analog quantity to directly control the output current of the drive board,You can now use onlyCTLInterface Control Board,AN2/POTAndCHSWThe interface does not access any signal。

2 Internal and external control control is required for applications,For example, a power box,Both the local signal,An external analog signal input port is also required。The local signal is generally provided by a potentiometer,Or it occurs by the local single chip Microcomputer,The signal of external control is provided by the user of the box。In this case, you can useCTLTheIcConnecting an external analog signal,AN2/POTDirectly connected to a10k(1k-100kWhatever you want)The potentiometer,OrIc2Local analog signal generated by single chip Microcomputer,And then useCHSWTheSWTo switch from internal control to external control。

3 For fast modulation current required(For example, the power switch of fiber laser)The application,You can useCTLTheIcInput current signal,AN2/POTTheIc2Enter the threshold current signal,And then directlyTTLSignal outputCHSWTheSWTo modulate the current。Of course,Analog direct modulation,Also only usedIcInput fast-changing Analog quantities,Is also possible。

Note,Modulation,Are generally not in0AAdjust with working Current,ButThe threshold to the operating current。0AThe words,First of all, it is not good for laser diode.,Because there is no maintained threshold current,Thermal shock will be at greater,The laser diode adverse。Secondly, the debugging performance is also very poor,Not only will it extend the time for the current to rise,Will also produce excess response time,Thereby reducing the modulation speed。