Description

HY-T50 Co2 Laser Power Supply 50w For 40w 50w Laser Tube

1.Specification

|

Input |

Input Voltage |

AC220V or AC110V(to be specified when placing order) |

|

|

AC frequency |

47-440HZ |

||

|

Cold Surge Current |

≤60A(AC220V Input) |

≤30A(AC110 Input) |

|

|

Current Leakage |

≤0.7mA(AC220V Input) |

≤0.4mA(AC110V Input) |

|

|

Output |

Max Output Voltage |

DC 25KV |

|

|

Max Output Current |

DC 20mA |

||

|

Efficiency |

≥90 percent (full load) |

||

|

MTBF |

≥10000Hours |

||

|

Response Speed |

≤1ms(from the switch Signal is given to the output current up to 90% of the setting current) |

||

|

Control Interface |

TTL level switch control; high or low effective level can be chosen (details refer to the control terminal specification) |

||

|

Withstand Voltage |

Input-Output, Input-Shell AC1500V 10mA 60S; Output negative is connected with machine shell. |

||

|

Protection |

can work in open-circuit condition for a short time (Require a good protective earthing and avoid arc between the positive and the machine shell) |

||

|

Environment |

Operating Temperature-10~40°C),Relative Humidity (RH)≤90 percent |

||

|

Cooling Way |

Force-Air Cooling (FAC) |

||

|

Dimension |

L×W×H=167*144*97 (mm) |

||

2.Main Features:

- Good compatibility: It can be applicable to 50W,40W and 30W laser tube.

- Fast response speed and effect.

- Dramatically lengthen the life of laser.

- Easy Control: The start and stop of laser can be easily controlled by TTL level. And there are protection switch to test the external water, ventilation, etc.

- Easy control of laser power: Both 0-5V analog signal and PWM signal can control the laser power.

- The power supply has open circuit protection: Under the condition of good protective earthing, the power supply can work in open-circuit for a short time, which could avoid the damage of laser power supply because of the bursting of laser tube, thereby enhancing the life of power supply.

- The power supply can take feedback interface which can be used in closed-loop control and testing the working current of laser.

- The power supply adds a new function, that is timely scene judging which part is damaged, laser tube or laser power.

- Application: acrylic sculpture, cut; fabric sculpture, cut; rubber sheet sculpture, cut, et.

3.Operation Instruction:

1) Laser Tube connection: (Referring to Power supply and laser device’s connection diagram

High voltage terminal (HV+) of HY-T50 power supply should be connected to the positive pole of

CO2 laser device. Current circuit of the power supply shall be connected to negative pole (laseroutput terminal) of laser device, through an ampere meter or directly.

2) Connection of control signal(Referring to Power supply and control board’s connection

diagram) The control signal shall be reliably connected to control terminal of the power supply HY-T50,and make sure the DAC output signal,the enclosure of laser device and the external computer with the power supply all connected together. the laser device shall work as expected. If no laser emission after on the laser device,should check the control signal is correct or not(include check the voltage specification and logic),if use PWM control as power control,should make sure f≥20KHz,Amplitude (peak value) ≤5V,Check and make sure protection switch WP’s connection is correct at the same time.

3)Voltage of power input: HY-T50 ‘s power input of the power supply shall be 220VAC/50Hz. If 110VAC required ,please

specify when placing order.

4)Others: A group of protection switches are also reserved for detection of water switch, fan switch, open-enclosure protection and so on.

4.Caution:

1.Water cooling system should be working properly when switching on laser device.

2.Circuit of high voltage output should not be open! (High voltage output terminals (positive and negative poles) shall be connected properly to positive and negative poles of laser device respectively.)

3. Attentions should be given to avoid any electric shock after the power supply being switched off.( The Insulation safety requirements should be 40KV between the terminal of output and “G”)

4. Well-grounded three-pole receptacle should be used.The enclosure should be well grounded to avoid electric shock.

5.The instruction of power supply and laser wiring diagram and terminals:

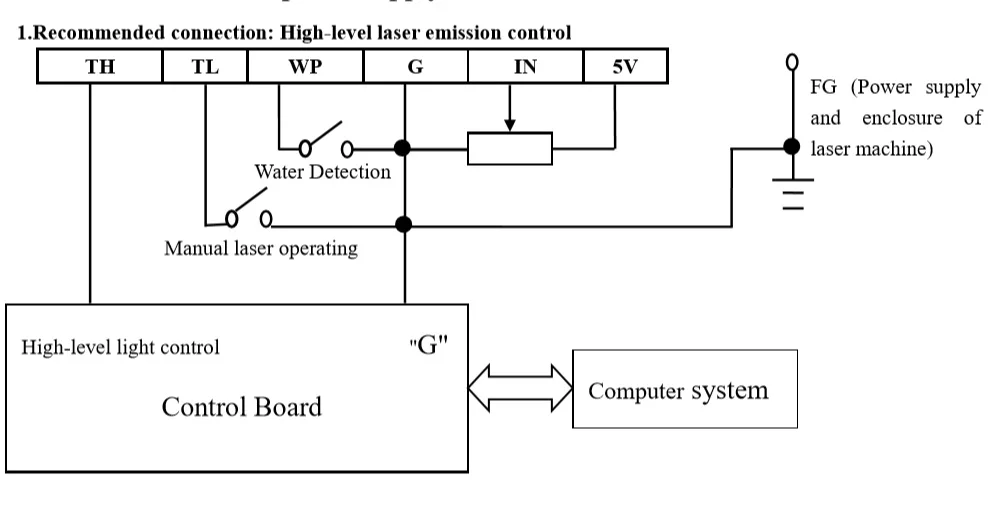

6.The Connection of power supply and control board: