Description

CO2 Steps no Screw Laser Engraving Logo Machine Laser Beam Expander

|

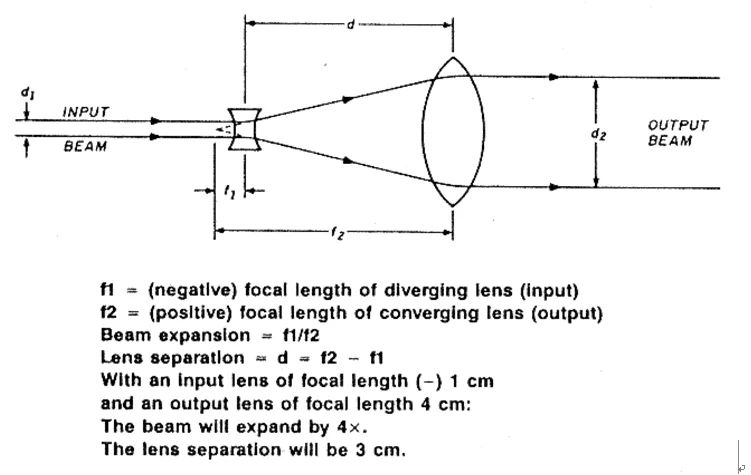

It is a device that take a collimated beam of light and

expand its size (or, used in reverse, reduce its size). |

| Specifiction |

|

PN |

magnification |

wavelength |

Material |

Input CA(mm) |

Output CA(mm) |

Dia(mm) |

Length(mm) |

|

BEH-10.6-4C |

4 |

10.6 |

Znse |

12.5 |

20 |

28 |

67 |

|

5 |

10.6 |

Znse |

12 |

22 |

30 |

72 |

|

|

BEH-10.6-8C |

8 |

10.6 |

Znse |

12.5 |

32 |

36 |

73 |

| Shape:Straight Mount without Screw |

| Professional Design |

|

Beam expander is composed with two lens of different curvature to obtain best effect. Master Laser TM beam expander has been proved to have perfect curvature with small divergence angle and less energy loss. |

| Replaceable Incident Mirror/ Eyepiece |

|

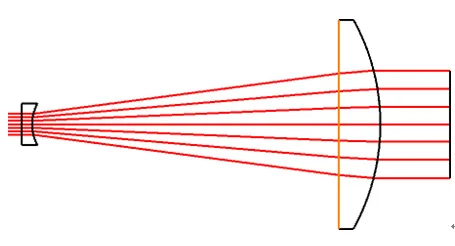

The role of beam expander is to expand beam spot.

The laser enter the beam expander where we called eyepiece, it is easily broken due to high power. The incident lens of beam expander produced by Master Laser TM is replaceable (we don’t suggest for other brands). |

| Polishing |

|

|

The light transmission of the parts increased by

cylindrical surface polishing, reduction or elimination on stray light of the optical system |

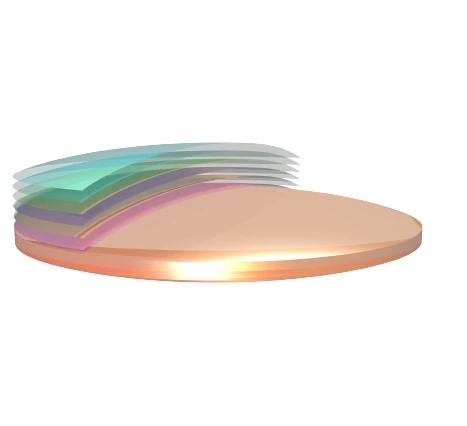

| Coating Film |

|

|

Double-side coated anti-reflection coating

The transmittance of working waveband in co2 laser industry reaches 99.9% Thin-film coating anti wiping Higher luminous flux Decrease or eliminate the reflective lights from optical lens |

| USA CVD ZnSe |

|

Adopted ZnSe material imported from USA which can

go with high power density, and increased the light transmittance of the parts CVD ZnSe imported from America, boasting low material absorption rate, excellent high-power density endurance, Great scratch resistance. |

| Shape & Structure |

|

Stable focus spot, better effect in cutting and engraving,

bearable for high power density, and strong thin – film coating against peeling off and durable for wiping. |

| Certifications |

| Service |