Description

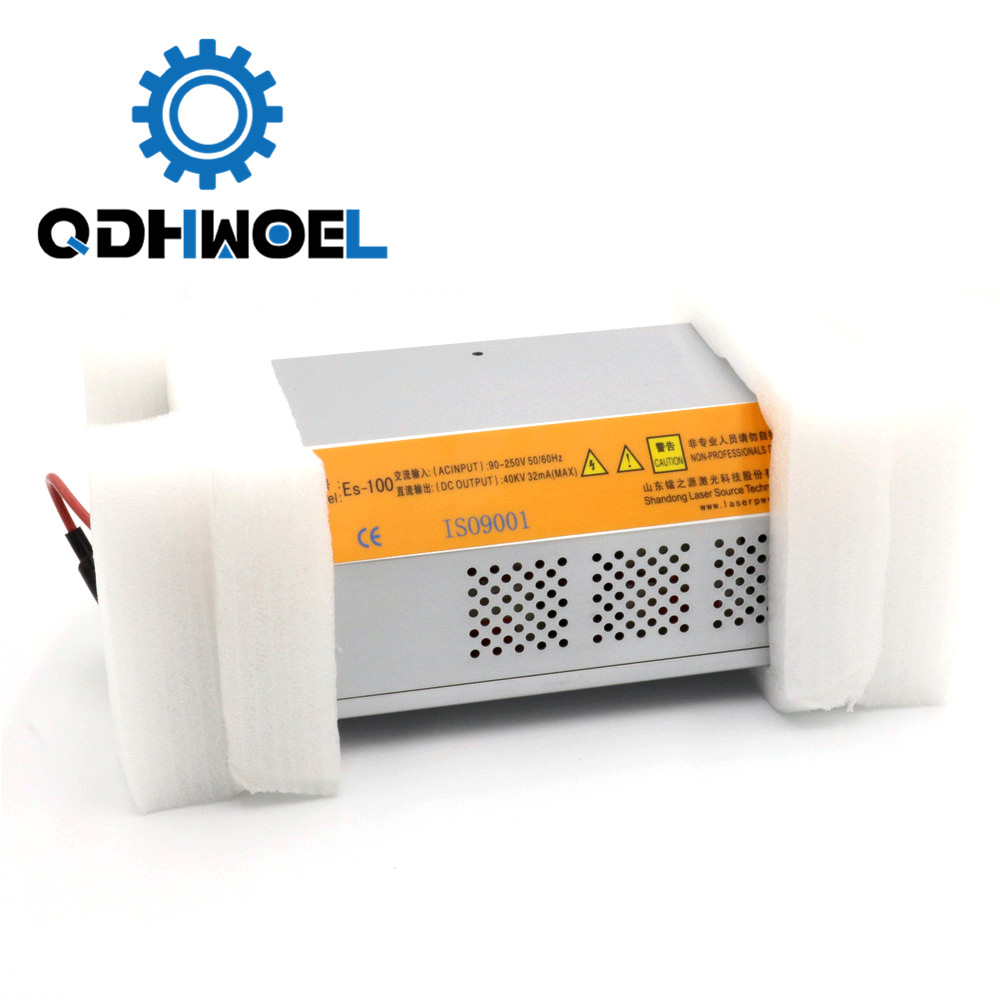

- Brand Name: QDHWOEL

- Model Number: 100-120W PSU HY-Es100

- Power: 100W

- Voltage: AC220V

- Warranty: 1 Year

- Certificate: CE&ISO9001

- Used For Tube: For 100-120W co2 laser tube

- Application: For co2 laser engraving and cutting machine

- Color: Silver gray

- Maximum Input Voltage: 45KV

- Maximum Output Current: 32mA

100-120W HY-Es100 Es Series CO2 Laser Power Supply for CO2 Laser Engraving Cutting Machine

Main Features:

1. 100w Laser Power Supply Main features:

1.Initiative PFC function, AC90-250V wide input voltage range, universal for all countries voltage.

2.Special design for outer shell, more beautiful appearance, better heat dissipation.

3.Improved current control mode, more stable laser, better compatibility, more adaptable for different kinds of laser tubes.

4.Simple power control, user can control laser with high or low level signal.

5.With test button, easy to test laser tube and power supply.

6.Small size outer shell, suitable for installing on the beam of cutting bed.

2. Es100 Laser Source Advantages:

1. Easy Control: The start and stop of laser can be easily controlled by TTL level. Both 0-5V analog signal and 5V PWM signal can control the laser power.

2. The Laser Power Supply has output open circuit protection.

3. This Laser power supply has TTL signal indication, water through signal indication and laser output indication.

3. Application:

HY-Es100 Laser Power Supply is used for 100W,120W Cutting and Engraving Acrylic, Fabric, Double Color

Sheet and Rubber,ect.

2.Parameters:

|

Input |

Input Voltage |

AC90V-250V |

|

AC frequency |

47-440HZ |

|

|

Max input power |

700w |

|

|

Max output current |

5A |

|

|

Output |

Max Output Voltage |

DC 45KV |

|

Max Output Current |

DC 32mA |

|

|

Efficiency |

≥90 percent (full load) |

|

|

MeanTime Between Failure (MTBF) |

≥10000 hour |

|

|

Response Speed |

≤1ms(from the switch Signal is given to the output current up to 90% of the setting current) |

|

|

Withstand Voltage |

Input-Output, Input-Shell:AC1500V 10MA 60S; Output negative is connected with machine shell. |

|

|

Environment |

Operating Temperature:-10~40°C),Relative Humidity (RH)≤90 percent |

|

|

Cooling Way |

Force-Air Cooling (FAC) |

|

|

Dimension |

L×W×H=278*144*104 (mm) |

|

|

Color |

Silver gray |

|

Terminal definition:

|

1 |

2 |

3 |

4 |

5 |

6 |

|

TH |

TL |

WP |

G |

IN |

5V |

Terminal definition as follow:

|

TH |

Input Signal |

The control of laser: TH≥3V, emitting laser; TL≤0.3V, no laser. |

|

TL |

Input Signal |

The control of laser: TH≥3V, no laser; TL≤0.3V, emitting laser. |

|

WP*1 |

Input Signal |

The control of laser: TH≥3V, no laser; TL≤0.3V, emitting laser. |

|

G |

GND |

This foot must be connected well with the shell of laser machine and the ground of control board. |

|

IN*2 |

Input Signal |

The control of laser power: Both 0-5V analog signal and PWM signal can control the laser power. |

|

5V |

Output Power |

Output 5V, the maximum output current is 20mA.

|

Laser power supply maintenance of common sense:

1, Before maintenance, check the power supply shell is normal grounding;

2, measuring power box shell on the work station or whether there is a voltage difference between the workbench

3, power box with high pressure on many places, after power on, hand can’t touch the metal parts of the device

4, Before replace the power box inside device ,turn off the power supply of the energy storage capacitor shall be discharged completely and voltage profile after confirm no voltage for the next step of replacement or repair measures

5, if the laser machine works unstable, or fall of work, can check circuit screw, terminal blocks, such as whether is loose, wiring the phenomenon such as oxidation.the old power supply or the power supply works under poor environment ,pay more attention on formation condition.

6 ,when maintenance,don’t tear down the internal cable tie and connecting wire, control panel, or cut disorderly change, is likely to cause the whole machine interference or performance degradation, and even cause scrap.

Fault Analysis of CO2 Laser Power Supply Not Working:

CO2 laser power does not work

(1) Maybe overvoltage protection action:

A. Please check whether the power supply output and the positive connection of the lamp are reliable!

B. may be damaged or lamp tube aging, breakdown voltage exceeds 35KV.

(2) Check that the AC input cable and the control wire are securely connected.

(3) Check the high-voltage output line for damage, leakage may lead to power in the work, but the lamp is not light!

(4) Power ground wire (not the power output of the black line but the first port of the AC input terminal see page 3 of the manual) is correct and reliable access to the earth.