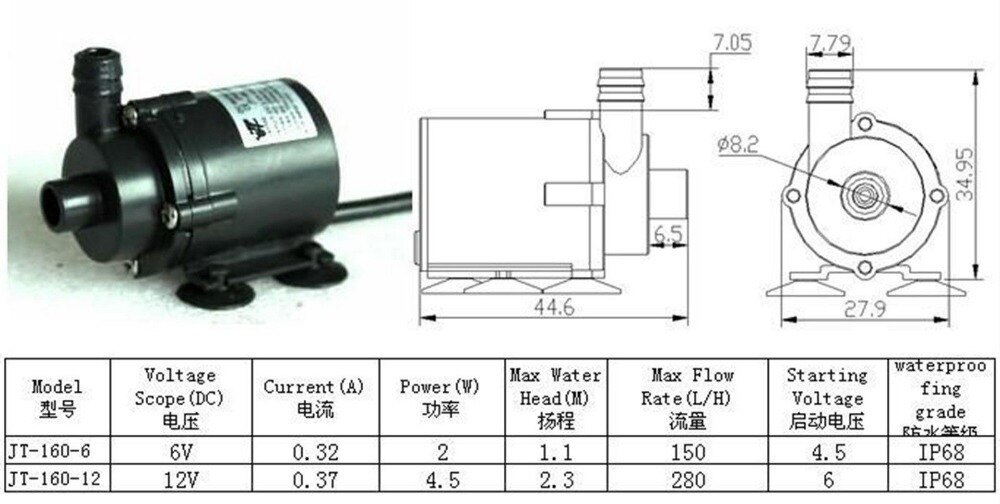

JT160. Amphibious pumps into DC3-6V, DC6-12V two specifications.

1 Suction: The best diving, land use suction 0.5 meters (must be water) Maximum lift: 1.8 m

2 can also be placed diving out of the water, not self-priming.

3 consecutive working life (ie, 24 hours non-stop work) greater than 20,000 hours, about 10 hours a day, pumps life of up to 8 years!

3 fully enclosed motor windings, using a unique formula resin casting, insulation, and never leaks. Corrosion.

4 inlet diameter of the outlet diameter 8.2MM 7.8MM, at the bottom of the pump with three soft suction cup, can easily be fixed.

5 can be used as a submersible pump use, you can also leave the water to work.

6 ultra-quiet, 10cm 30dB noise index

Mainly for computer water cooling, solar technology fountains, cooling equipment, medical, aquarium. Pumps use environmentally friendly materials, aquarium best choice. Products through ROSH/IP68/CE/EMC certification! 1 year warranty!

Note: The use of ultra-high voltage illegal use or cause the product to burn, shop the right to waive all service!

Pump is just an accessory, once burned beyond repair, because we can not control the use of the buyer, except the product firmware appears missing, the pump is not allowed to replace damaged or return. Please be advised! Do not agree, please carefully shot!

Friendly reminder: the former can not be used to determine its own supply voltage, measured with a multimeter good first re-energized. Do not reverse!

Wiring: White Line is positive and black line is negative.If you received the brown and blue,the brown line is positive,and blue line is negative.

Brushless DC Pump (new magnetic isolation pump) advantages

Magnetic pump is a non-contact torque transmission is achieved thereby static seal instead of dynamic seal, the pump reaches complete solution to the “run, run, drip, leak” issue, eliminating the refining and chemical industries through magnetic drive flammable, explosive , toxic, harmful media through the pump seal leakage security risks, effectively ensuring the health and safety of production workers.

Advantages:

Compared with the brushless DC motor pumps, magnetic drive pump has the following advantages:

1. Enclosed by a dynamic seal the shaft becomes static seal, completely avoiding the media leaks. You can amphibious, and completely waterproof.

2. No separate lubrication and cooling water, reducing energy consumption.

3. Low power consumption, high efficiency, and has a damping effect, reducing the impact on the motor vibration motor vibration when cavitation effects on pump and pump occur.

4. Overload in ceramic rotor shaft slipping on motors, pumps have a protective effect

5 Brushless DC Pump uses a commutation of electronic components without the use of brushes commutation, wear-resistant high-performance precision steel shaft and sleeve, the sleeve and the magnet even by injection into a whole thus avoiding wear and tear, so brushless DC magnetic pumps of life is greatly enhanced. The stator and rotor parts of the magnetic part of the pump is completely isolated isolation, stator and circuit board part with epoxy potting, 100% waterproof, permanent magnet rotor magnet part of the pump body using environmentally friendly materials, low noise, small size, performance stable. You can adjust the various parameters required by the stator winding, wide voltage can run.

Advantages: long life, low noise up to 35dB or less, can be used for hot water circulation. Part of the motor stator and circuit board using epoxy potting and with the rotor completely isolated, you can install and completely waterproof underwater pumps axis high-performance precision steel shaft, high precision, high shock resistance.

Brushless DC water pump (magnetic pump) works

Brushless DC magnetic drive pump impeller magnet motor is composed of integrally molded into the rotor, the rotor is directly injection molded intermediate sleeve is fixed to the housing, the stator part of the motor and the circuit board by using a high-performance ceramic shaft epoxy potting at the pump, there is a layer of thin-walled isolation between the stator and the rotor, without with traditional mechanical seal, so it is completely sealed. Torque motor is energized by the silicon steel coil (stator) driven by a permanent magnet generates a magnetic field on a magnet (rotor) job running. Magnet be n (n is even) level magnetizing the magnet portion coupled to each other to form a complete magnetic systems. When the poles of the magnet poles of the stator coils in different poles relative to that displacement angle Φ between two poles = 0, then the minimum magnetic energy magnetic system; When turning to the same extreme opposite pole, ie between the two poles of displacement angle Φ = 2π / n, this time the maximum magnetic energy magnetic system. After removing the external force, the magnetic poles repel each system, the magnet will be restored to the magnetic force of the magnetic energy of the lowest state. Thus the magnet in motion, the magnetic drive rotor.

Brushless DC Pump by electronic commutation, without the use of brushes, a magnet rotor and stator magnetic silicon steel has a multi-stage, when the rotor relative to the stator magnet rotation angle automatically changes the direction of the magnetic poles of the rotor always maintain the same level of rejection, brushless DC isolated so that the magnetic field has a higher speed and the pump efficiency.

Magnetic isolation of the stator and rotor pump is completely isolated, completely avoid the traditional type brushless DC motor pump fluid leaks exist. And can be fully and completely waterproof diving, effectively improve the life and performance of the pump.

Applications:

Can be used for computer cooling system, solar fountain, Desktop fountain, crafts, coffee machine, water dispenser, tea, a pourer, soilless cultivation, shower, bidet, scaling, water heaters pressurized plumbing mattresses , hot water circulation, filtration pool water circulation, foot massage basin, massage bathtub, car cooling system, fuel, humidifiers, air conditioners, washing machines, medical equipment, cooling systems, sanitary products.