Description

Product Description:

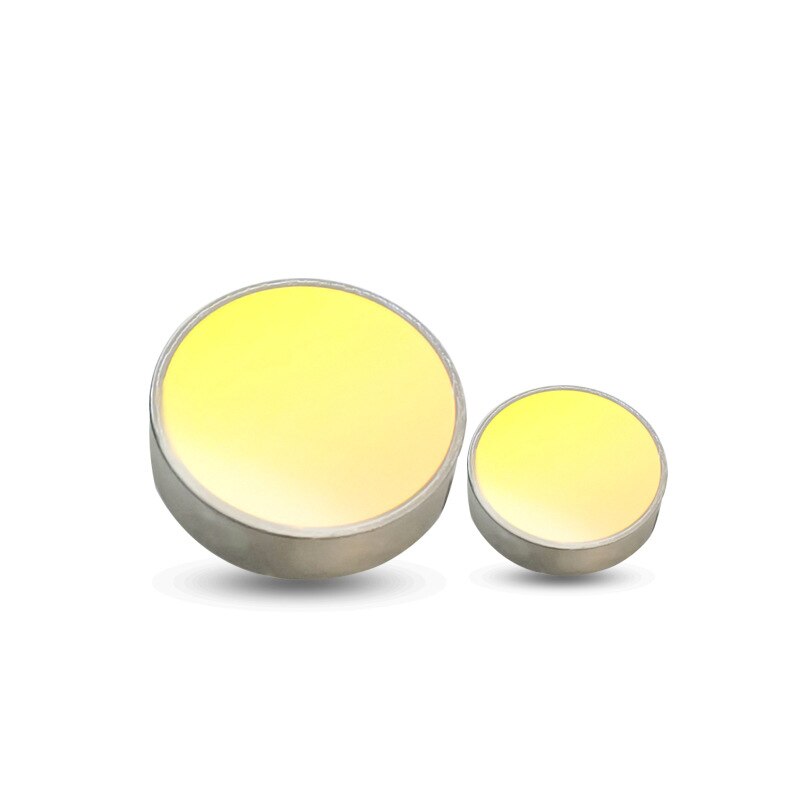

Holographic concave grating 1100 lines used on various spectroscopic instruments, diffraction grating concave grating:

Specification:

Surface Quality : 20-10

Wavelength: 600nm

Diffraction gratings can separate polychromatic light (white light) into various components (through diffraction effects). Various gratings are made by multiple copies of high-precision master gratings.

High-quality instrument-grade gratings can almost meet all diffraction requirements, especially when efficiency requirements are relatively high. The grating can be selected according to size, groove pitch and blaze wavelength. The theoretical resolution is proportional to the number of grooves per millimeter of the master grating, and the blaze angle and grating pitch determine the maximum efficiency of the special wavelength and spectral region.

Diffraction grating ruler can be used in various monochromatic light research, teaching, and industrial occasions. Almost all commercial spectrophotometers (ultraviolet light, visible light, infrared light, fluorescence, Raman light, atomic absorption, etc.) use diffraction gratings. Select a specific wavelength or scan the entire wavelength area. For an ordinary grating ruler, the grating is usually copied at peak efficiency. When copying holographic gratings, stray light needs to be adjusted to a minimum, and a high-resolution master scale is required.

Note: The damage threshold of grating ruler and holographic grating ruler is 350mj/cm2 under pulse laser, and 40Watts/cm2 under continuous laser mode.

How to make a ruled diffraction grating

The engraved diffraction grating is a series of dense parallel lines with equal spacing and line width carved on an optical substrate coated with aluminum film, usually called “master ruler”. A high-precision interferometric drive is used to control a diamond knife to score according to the set pitch and angle, forming a jagged flute (usually called the blaze angle).

When copying, first vacuum deposit a thin film layer on the mother board, then plate a layer of aluminum film on the separation layer, and then plate a layer of epoxy layer on the top layer, copy the groove surface, and then separate the mother grating, the end manufacture.

Detailed Images: