Place orders for 355nm DPSS laser at BeamQ.

3 Types of 355nm DPSS Laser:

CW 355 nm Lasers

CW 355 nm DPSS Lasers are ideal for applications requiring up to 20 mW of 355 nm UV laser light with a long operating lifetime . These lasers are commonly used for fluorescence excitation and a broad spectrum of other applications.

Passively Q-switched 355 nm Lasers

Passively Q-switched 355 nm DPSS Lasers are ideal for applications requiring a short wavelength or high photon energy. These lasers are commonly used for fluorescence excitation, Raman spectroscopy, material processing, and a broad range of other applications.

AOM Q-switched 355 nm Lasers

AOM Q-switched 355 nm DPSS Lasers are ideal for applications requiring the highest available peak power and/or single pulse energy at 355 nm. The embedded AOM gives the user direct control over the output pulses, enabling a specified frequency or even a single pulse to be emitted. These lasers are commonly used for materials processing, marking, Raman Spectroscopy, biological experimentation and a broad spectrum of other applications.

The applications of 355nm DPSS laser

1 UV Laser SLA 3D Printing Samples

SLA 3D Printer use 355nm UV laser light to cure light-reactive thermoset resin into hardened plastic. When SLA resins are exposed to UV laser light, short molecular chains join together, polymerizing monomers and oligomers into solidified rigid or flexible geometries.

2 UV laser can apply to most universal plastic and some engineering plastics, such as PP, PE, PBT, PET, PA, ABS, POM, PS, PC, PUS, EVA, etc., and plastic alloy, like PC/ABS and other material. The marking is clear and bright, and can mark black and white color on natural color plastic, white plastic, colored plastic and black plastic. Successful commercialized application in the plastics include animal ear tag, light switch cover, cosmetic packaging material, vehicle interior button and doorknob, instrument panel, ABS keyboard, HDPE, PET and PVC rigid container and container cover, nylon and PBT automobile and non-automobile electrical connector, engine hood element such as fuse box and air cap, anti-counterfeit labels, container lock catch, stationery, home appliance shell, etc.

3 Glass material processing

Since the focal spot of UV laser is very tiny and processing temperature is low, furthermore as a non-contact marking technology, UV laser is very suitable to mark glass material. Successful UV laser commercialized applications include wine bottle, flavour bottle, drinking bottle and other industries glass bottle package and glass tableware, glass crafts gifts, crystal marking, etc. Besides marking glass directly, UV laser can also remove paint or coat on glass to form text or pattern, like logo, number or other patterns;

4 Leather Marking

5 Ceramic Marking

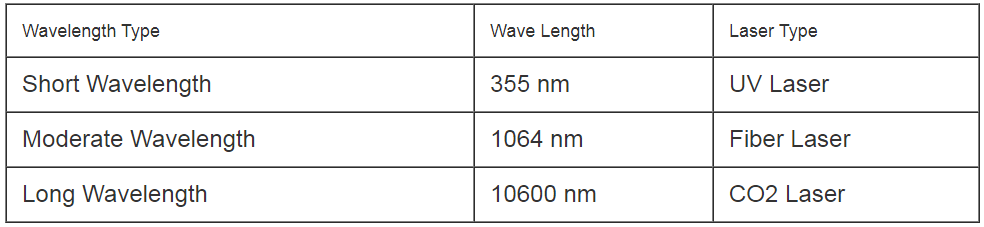

Comparison among 355nm UV Laser, 1064nm Fiber Laser and 10600nm CO2 Laser

1) The shorter the wavelength, the more concentrated the energy. The greater the energy, the more light that material will absorb. Greater absorption = Better quality mark. Compared with long wavelength 1064nm fiber laser and CO2 laser, 35nm UV laser can make better quality mark;

2) UV lasers are generally used for intricate, precise marks on the micro level. Their focused wavelengths allow for a high beam intensity and miniscule spot size;

3) UV laser are especially suitable for laser marking soft materials. Because it offers a higher absorption rate than fiber and CO2 lasers and are less likely to burn the surrounding material because they produce less heat. This is why UV laser is also referred to as “cold processing method”, while fiber and CO2 lasers are called as ‘thermal processing method’;

4) Fiber / CO2 laser marking machine can alter or even burn some heat-sensitive materials, like plastic, leather, etc. This is because the laser energy is not fully absorbed, allowing too much light to pass through without marking the material. You’re left with indecipherable logos, unreadable barcodes, or damaged parts.