Compression fittings are used to create leak-free tube connections easily and quickly. Double ferrule compression fittings feature an outer nut, two deformable ferrules in soft alloy or non-ferrous metals and, a tube fitting body and are available for metric and fractional tube sizes. When the fitting nut is screwed on the tube, the ferrules get deformed to create a tight seal. Swagelok and Parker are the two main players in the compression fittings market.

Compression fittings allow the connection of two imperial tubes (or fractional tubes), two metric tubes or, also, the connection of a metric tube at one end and a fractional/imperial tube at the other end.

A common size range is between 1/16″ and 2″ for fractional sizes and between 2 and 50 mm for metric sizes).

Compression tube fittings are rated to the maximum working pressure of the tubing to be installed.

Double ferrule compression tube fittings are largely used across multiple industries, such as downstream petrochemical, pulp & paper, laboratories, aeronautical and shipbuilding, defense, power generation, semiconductors manufacturing, and heavy industries.

HOW TO INSTALL COMPRESSION FITTINGS

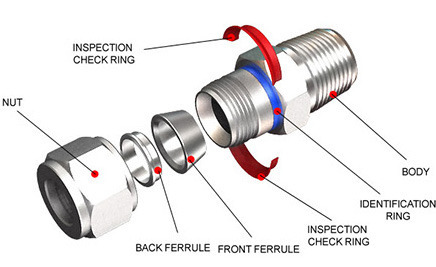

The tube has to be inserted into the fitting and the nut has to be screwed. By doing this, the back ferrule advances axially towards the front ferrule and applies an effective grip on the tube.

The ferrule is deformed, compressed and clamped around the tube creating a very tight seal able to withstand the nominal pressure of the tubing.

The two-ferrule design compensates the tolerances in tube diameter, wall, thickness, and material hardness, giving the connection exceptional leak-free performance (without impacting the mechanical properties of the tubing: the back ferrule moves according to a predefined path without reducing or stressing the inner diameter of the tube).

The connecting tube, at the outlet of the fitting, can be screwed or welded on the compression tube fittings (depending on fitting end type). Multiple options are available in terms of screwed ends (NPT, ISO, etc).

A joint made with a ferrule fitting can be disassembled for maintenance (spare ferrules and nuts are available).

By using some basic tools, provided by compression tube fittings manufacturers, the installation is smooth and quick. No welding is required.

As shown in the video above, a proper force shall be applied to the nut when screwing it on the tube otherwise the fitting may get damaged and the connection might leak. It is recommended to tighten the nut manually at first and then use an appropriate wrench.

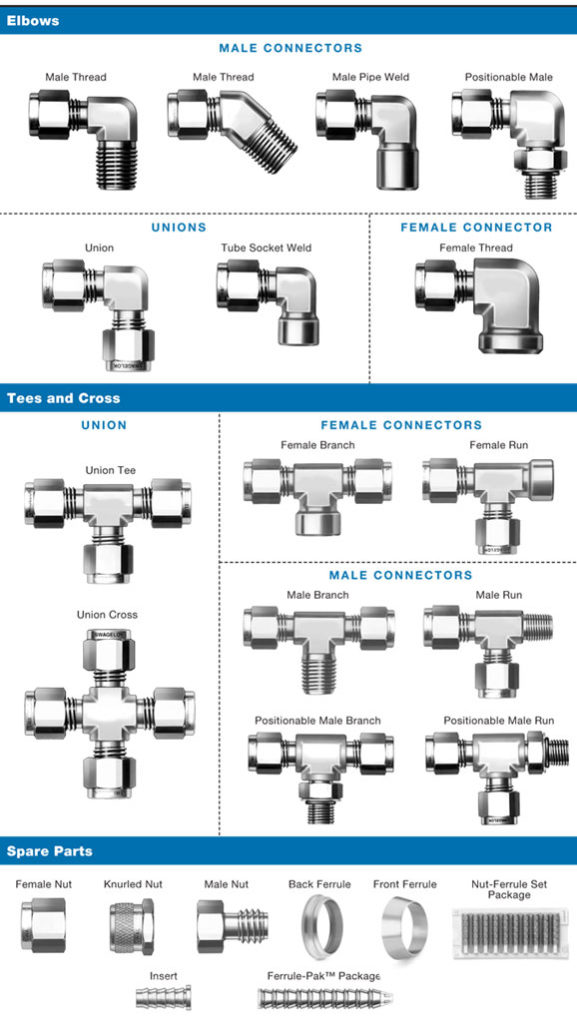

COMPRESSION FITTINGS TYPES

Compression tube fittings (ferrule) can be grouped into the following families:

Connectors (male connector, female connector, bulkhead male connector, bulkhead female connector, butt weld pipe connector, socket weld tube connectors)

Male and female elbows

End closures (tube, fitting)

Reducers

Tees (male run tee, female-run tee, male branch tees, female branch tees)

Unions

All these tube fittings are shown in the image below: